Introduction

Building a keeping wall is more than just stacking stones or positioning lumber; it's an art that mixes engineering concepts, style aesthetic appeals, and useful performance. As we explore From Concept to Completion: A Day in the Life of a Retaining Wall Builder, you'll find the complexities involved in this remarkable occupation. Whether it's managing concrete sleepers, H beams, or lumber sleepers, every element plays a critical role in ensuring that the structure not only looks excellent however likewise stands the test of time.

What is a Retaining Wall?

A maintaining wall is a structure designed to keep back soil and avoid erosion on sloped surfaces. These walls are crucial for maintaining landscape integrity and can be made from numerous products such as stone, wood, and concrete.

The Role of a Retaining Wall Installer

A retaining wall installer is responsible for changing plans into concrete structures. They work carefully with designers and landscape designers to ensure that the completed product fulfills both functional and visual criteria.

Understanding the Various Types of Retaining Walls

Concrete Sleepers

Concrete sleepers are pre-cast blocks follow this link utilized for their toughness and resilience. They supply outstanding assistance for heavy loads and are resistant to rot and pest damage.

H Beams

H beams provide considerable structural support due to their shape, making them perfect for taller maintaining walls where additional strength is required.

Wood Sleepers

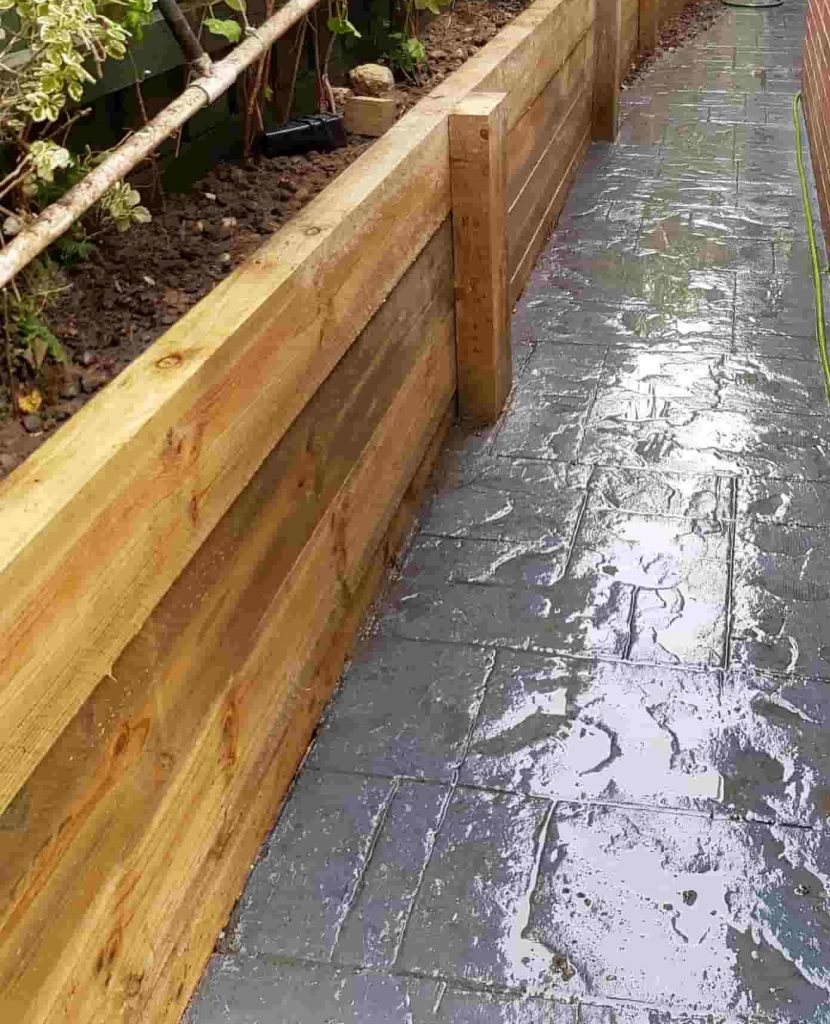

Though aesthetically enticing, wood sleepers require regular upkeep due to their susceptibility to decay. However, they can supply a warm visual that mixes well with natural landscapes.

Timber Sleepers

Timber sleepers are typically used in domestic projects where less height is needed. They can produce a rustic charm but included concerns about longevity.

Stone Retaining Walls

Stone walls are ageless and can add enormous worth to properties. Their natural look makes them popular in landscaping styles but requires skilled workmanship for appropriate installation.

The Initial Consultation: What Occurs First?

During the preliminary assessment stage, a retaining wall contractor meets with customers to discuss their requirements and preferences. This stage includes website evaluations, comprehending drainage concerns, and figuring out material choices.

Planning & Style Stage: Crafting the Blueprint

Once preliminary conversations conclude, comprehensive plans are created. This strategy consists of measurements, material specifications (be it concrete sleeper or stone), and drain solutions.

Permits & Regulations: Browsing Legalities

Before building and construction begins, protecting required licenses is crucial. Building regulations vary by area; for this reason understanding regional regulations makes sure compliance throughout the project.

Preparing the Site: Cleaning & Excavation Work

Preparing the site involves cleaning vegetation and debris followed by excavation work. This step lays the foundation for a structurally sound retaining wall.

Material Selection: Picking The Right Components

Selecting products lines up closely with design objectives while also thinking about budget restrictions. Factors like sturdiness (concrete vs. timber sleeper) play an essential function in this decision-making process.

Foundation Work: The Importance of Stability

A solid structure is non-negotiable when constructing any retaining wall. Whether using H beams or stone, guaranteeing stability avoids future collapses or shifts.

Construction Process: Step-By-Step Execution

Lay Out The Plan

Utilizing stakes and string lines assists envision where each element will go.

Excavate For The Base

Digging down guarantees that water will drain pipes appropriately far from the wall.

Install Drainage Solutions

Proper drainage systems prevent soil saturation behind walls.

Constructing The Wall

Depending on selected materials (like concrete sleepers), walls might be developed layer by layer.

Backfilling

Once set up, backfilling assists stabilize the structure while ensuring adequate drainage.

Finish Work

Adding any desired features like caps or decorative components finishes the look.

Tools of The Trade: Essential Equipment For Builders

Having a variety of tools available makes all jobs simpler:

- Shovels & & Picks Levels Compactors Trowels Power Tools

Quality Control Procedures During Construction

Quality control guarantees that every aspect meets industry standards:

- Regular Inspections Material Testing Adherence To Plans

Addressing Obstacles On-Site: Problem-Solving Skills Required

No building and construction job goes off without a drawback! From unanticipated weather changes to material lacks-- being adaptable is key!

Final Touches: Aesthetic Enhancements For Your Retaining Wall

After building comes beautification:

Landscaping around it Adding plants or lighting Painting or staining wood structuresMaintenance Tips For Longevity Of Retaining Walls

To extend the life of your retaining wall:

- Regularly inspect for fractures Clean particles Check drainage systems

Common Frequently asked questions About Maintaining Walls

1. What products are best for building retaining walls?

Choosing in between concrete sleeper, stone, timber sleeper depends on visual choice and structural requirements.

2. How high can my retaining wall be?

Local policies determine height limitations; normally between 4-- 6 feet without unique permits.

3. Do I need planning permission?

In most cases yes; check regional building codes before starting construction.

4. Can I install a retaining wall myself?

While DIY is possible, employing professionals guarantees security and compliance with regulations.

5. How do I maintain my maintaining wall?

Regular evaluations should focus on checking for cracks or drain problems; immediate repair work improve longevity!

6. Are retaining walls expensive?

Costs differ based upon products chosen(e.g., wood vs stone)together with labor costs involved.

Conclusion

In conclusion, building a retaining wall includes precise planning from start to complete-- thus why comprehending every step in this journey from principle through completion matters profoundly! From picking products like concrete sleepers or timber to navigating legal requirements-- it's clear how comprehensive this procedure truly is! So next time you see one standing tall against nature's forces-- take a moment to value all that went into developing it!